Bulk Bag Unloading System

Bulk bag unloading system. Every NBE bulk bag discharger regardless of its particular design or application operates on a process-specific fully welded structural framework chassis. Is a world leader in supplying Bulk Bag Discharging Systems. Product compaction during storage or transport Single or multi trip lined or unlined Bulk Bags or Flexible Intermediate bulk containers FIBCs.

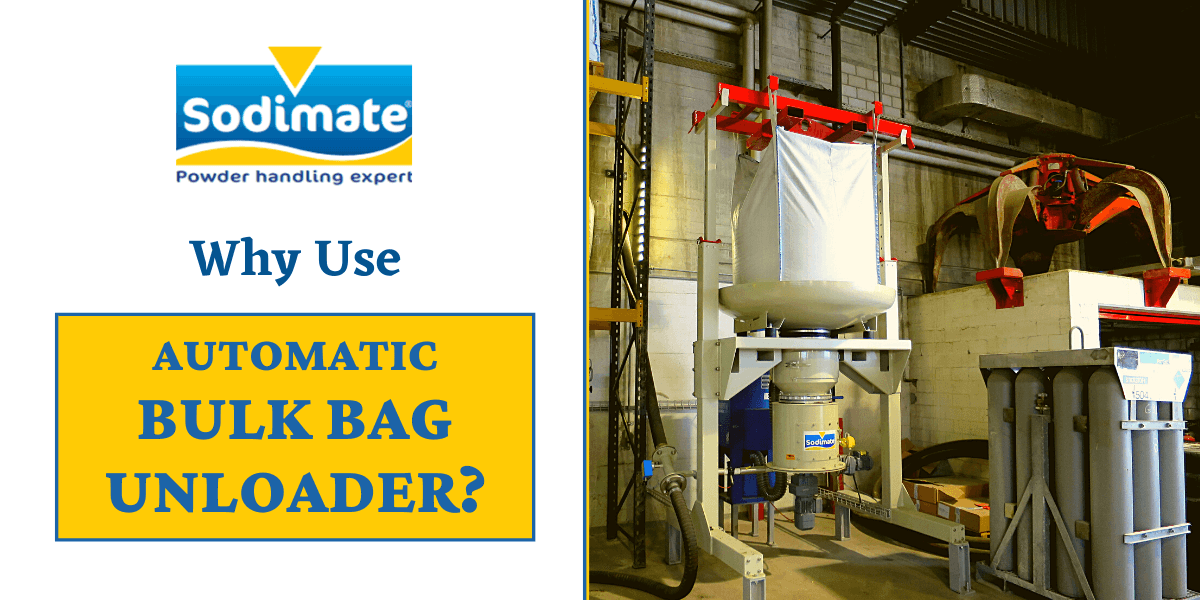

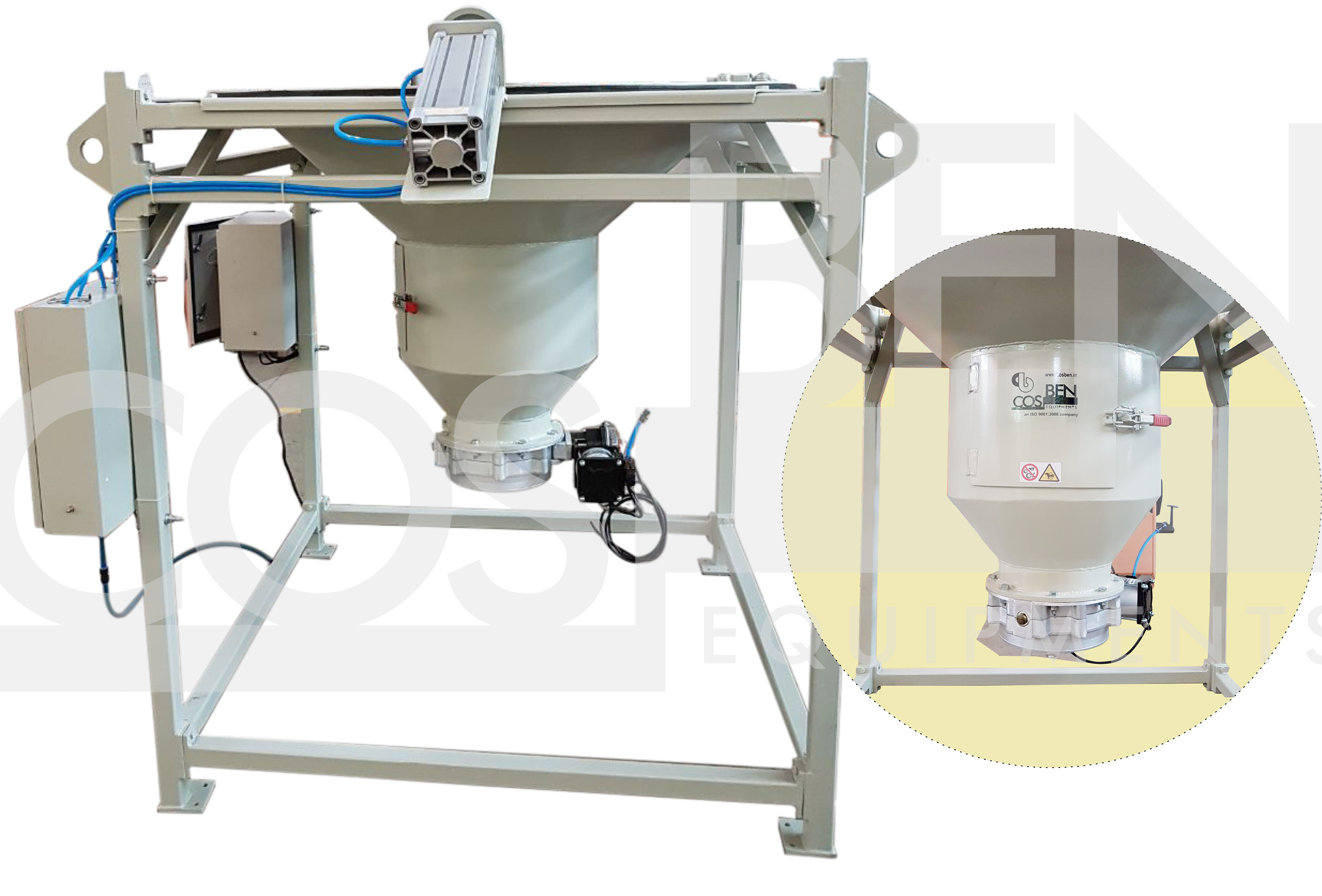

The PPS bulk bag unloader system provides an easy and safe method to lift support and discharge bulk bags. These include hoist and trolley bag agitators to facilitate unloading iris valves and dust containing discharge. Many low cost bulk discharge systems rely on forklift loading.

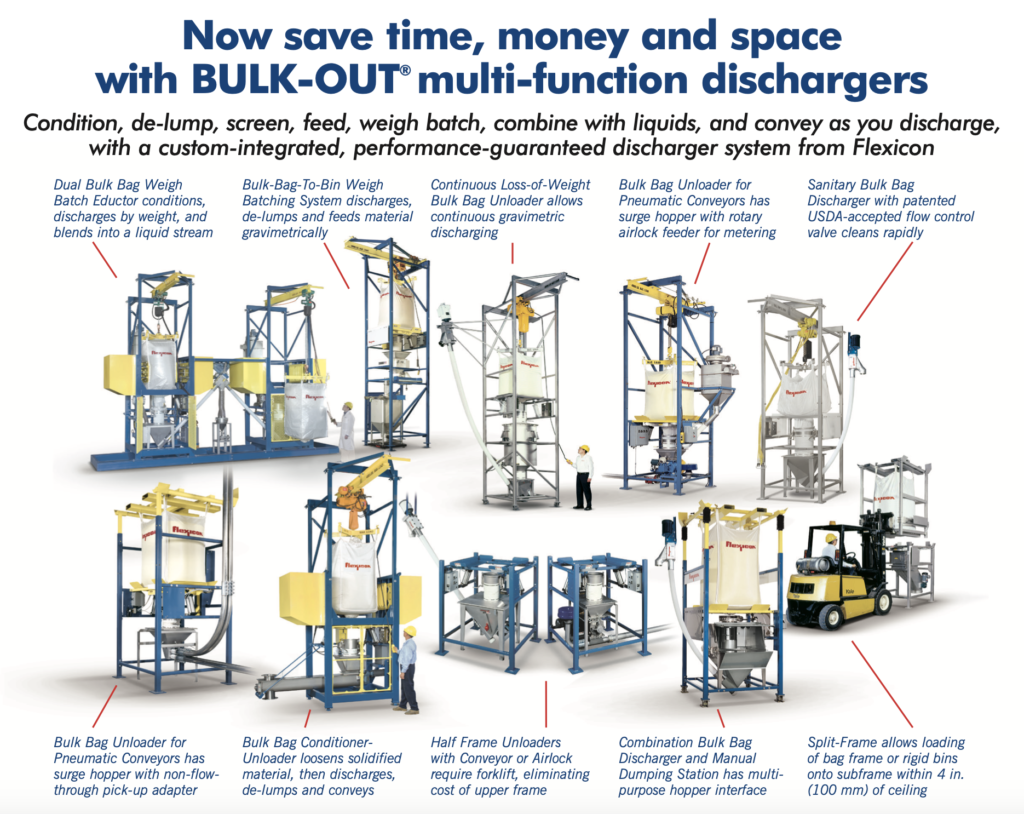

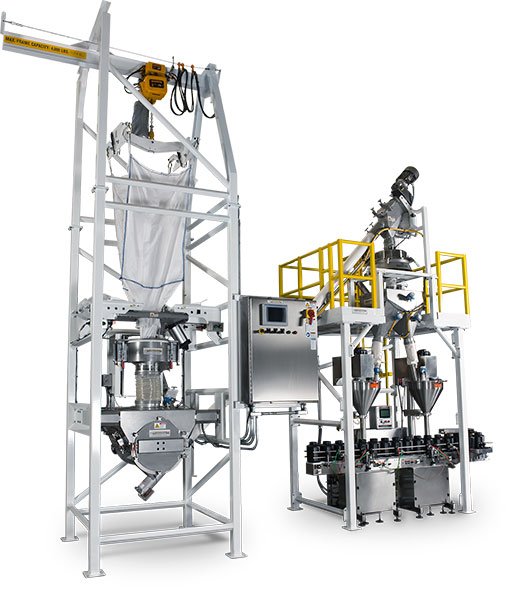

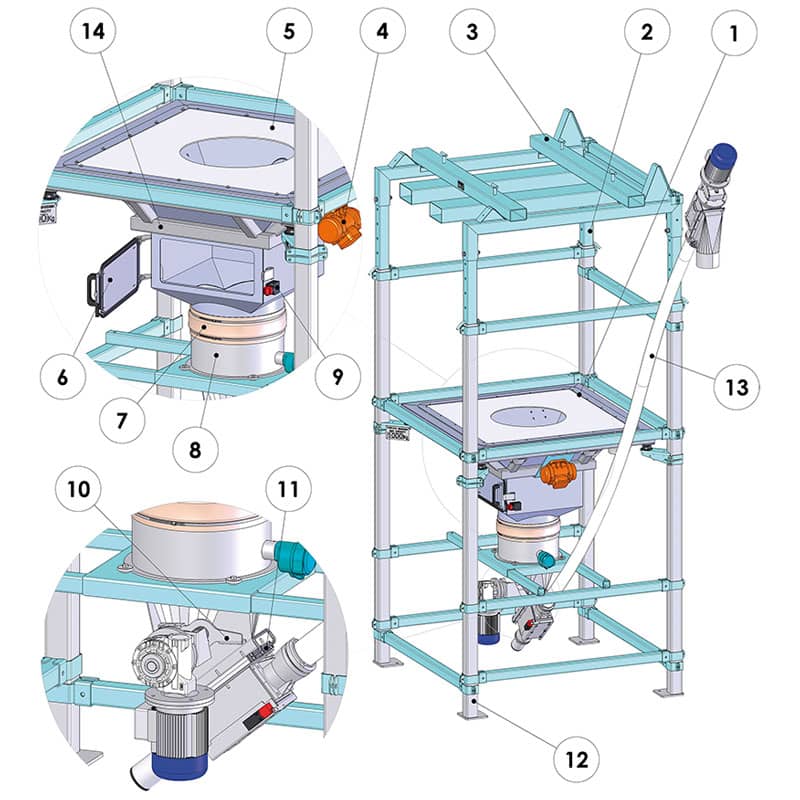

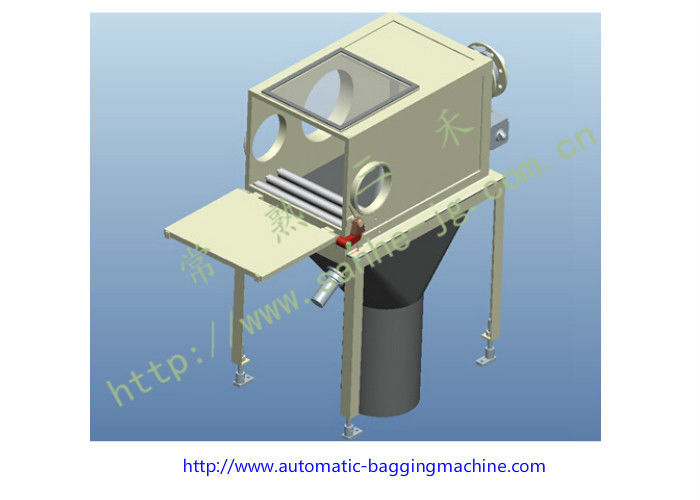

Our bulk bag unloaders are designed to fit your specific requirements and our systems can be designed to handle all types and sizes of bulk bags. Bulk bag unloaders also called bulk bag dispensers or super sack unloaders typically consist of a steel frame that supports the unloading of material from a FIBC super sack into the industrial process. Flexicon BULK-OUT Bulk Bag Dischargers also known as FIBC Big Bag and Jumbo Bag unloaders are offered in numerous frame configurations.

The Young Industries Inc. Configure your own bulk bag unloading system to get a free quote and drawing. The availability of multiple Models and Options ensures the right customization to meet your exact needs.

We are specialists in the handling of TIO2 and other hard-to-handle products by using TransFlow Technology in bulk bag unloaders bin dischargers rotary valves and conveyors. Our unique inflatable spout design seals the bag spout inward against the unloader spout. Every Spiroflow bulk bag unloader comes standard with a dish designed for operator safety.

This system allows unloading of bulk bags in as little as 8 ft. Find the bulk bag unloading system you need to reduce material costs improve worker safety and much more. The Low Headroom DFB Unloader is specifically designed for those applications where conventional unloading methods will not work.

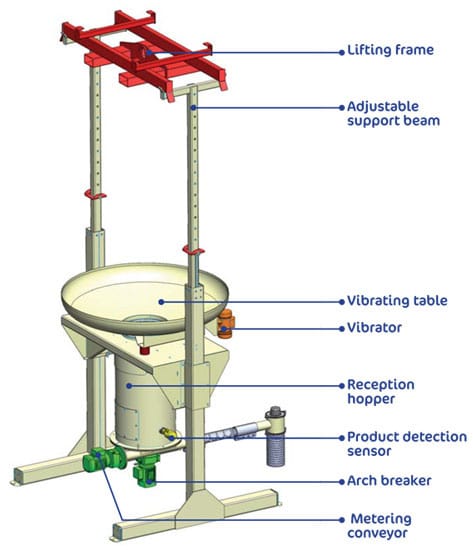

These systems can consist of some or all of the following main components. We design and manufacture equipment ranging from a single Bulk Bag Un.

The SoliValve or a pinch valve will automatically adjust to slow down and stop material flow to hit the target weight and to allow for partial bag unloading.

Also known as Bulk Bag Unloaders Active Weighing Solutions Bulk Bag Unloading Stations are designed efficiently handle application variables such as. We design and manufacture equipment ranging from a single Bulk Bag Un. Customized bulk bag unloading systems can include bulk bag discharging crane bag lifts bag massagers dust containment and collection systems tramp metal separation material weighing batch dispensing complete controls for automatic operation can be incorporated into automatic batching and weighing systems and more. Whirl-Air-Flow can provide you with a bulk bag unloader that effectively meets your process requirement needs. Product compaction during storage or transport Single or multi trip lined or unlined Bulk Bags or Flexible Intermediate bulk containers FIBCs. Hapmans Bulk Bag Unloaders are designed and built to maximize the efficiency of your Bulk Bag Unloading operation. The availability of multiple Models and Options ensures the right customization to meet your exact needs. Spiroflow knows bulk bag unloading. Bulk Bag Unloading System.

Bulk bag unloaders also called bulk bag dispensers or super sack unloaders typically consist of a steel frame that supports the unloading of material from a FIBC super sack into the industrial process. Bulk bag unloaders also called bulk bag dispensers or super sack unloaders typically consist of a steel frame that supports the unloading of material from a FIBC super sack into the industrial process. Bag Lift Frame with Liner Clamp. These include hoist and trolley bag agitators to facilitate unloading iris valves and dust containing discharge. This system allows unloading of bulk bags in as little as 8 ft. We are specialists in the handling of TIO2 and other hard-to-handle products by using TransFlow Technology in bulk bag unloaders bin dischargers rotary valves and conveyors. The IBC2000 can be easily modified with a number of options in order to handle your specific requirements.

Post a Comment for "Bulk Bag Unloading System"